Indenting, Import & Supply

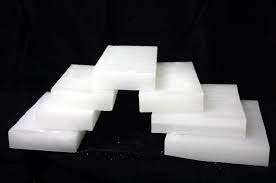

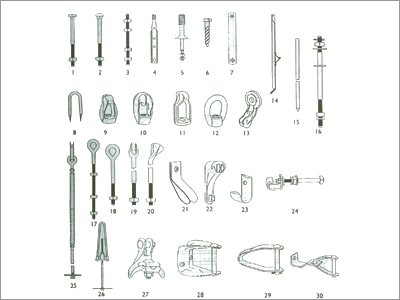

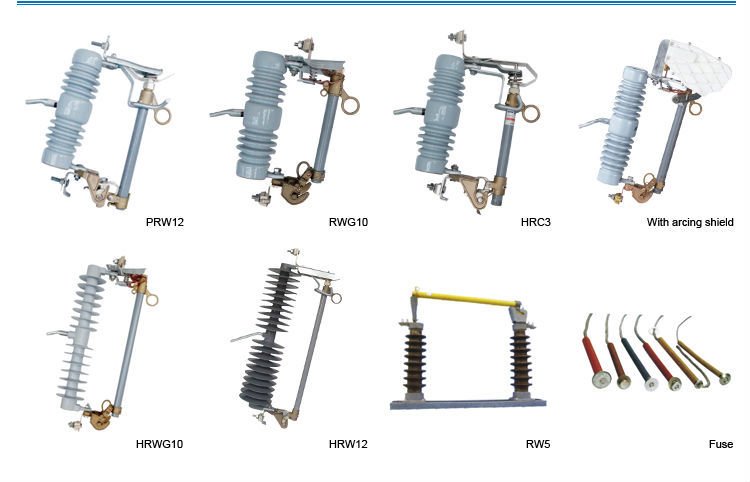

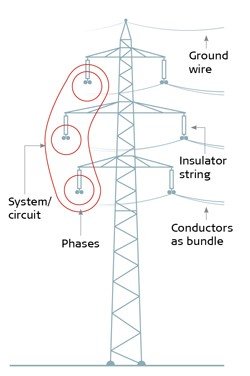

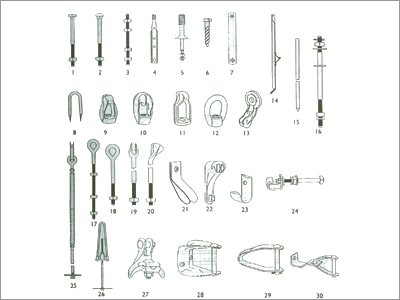

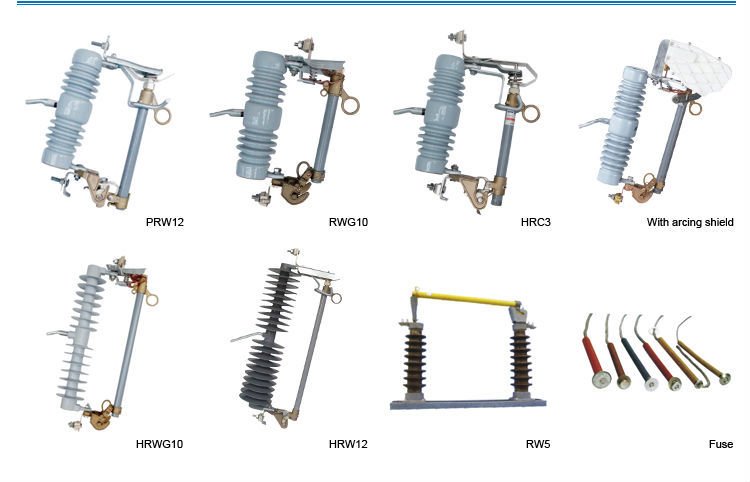

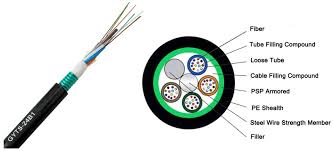

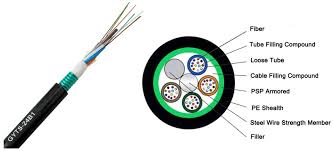

Major Electric Products including Meters, Transformers, Sub-Stations, Power Cables, Capacitor Bank & Switchgears, Insulators, Aluminium and Copper Wires, Steel and Steel Wires, Zinc Ingot, Coated Steel Tapes, HMS 1&2 80/20 Scrap, Silicon Electrical Steel Sheets, Filler Rod, PBT Granules, FRP, MDPE, M.S. Plate, LRS/ABS/NKK/GL/CCS/ Grade-A etc.

Alkali Chemical, PVC Resin, DOP/DPHP/Equivalent, HDPE, Petroleum Jelly, Chalk Powder, Thixotropic, China Clay, Plaster of Paris, Calcined Bauxite, Drawing OIL, Transformer OIL, Potassium Carbonate, Para formaldehyde, Para formaldehyde, Soda Ash, Caustic Soda, Clinker, Rock gypsum, Pulp, LDPE, Rock Phospate, Sodium Sulphate etc.

| Grade(Test Method) | H-58 | H-61 | H-66 | H-73 | H-80 |

|---|---|---|---|---|---|

| K-value(ISO 1628-2) | 57-59 | 60-62 | 65-67 | 72-74 | 79-81 |

| Degree of Polymerization | 700±50 | 800±50 | 1000±50 | 1350±50 | 1800±100 |

| Bulk Density(g/cc)(ISO 60) | 0.57±0.04 | 0.57±0.04 | 0.54±0.04 | 0.51±0.04 | 0.49±0.04 |

| Particle Size(45 mesh pass %) | ≧99 | ≧99 | ≧99 | ≧99 | ≧99 |

| (Honeywell SRA-150)Volatiles(%)(ISO 1269) | ≦0.3 | ≦0.3 | ≦0.3 | ≦0.3 | ≦0.3 |

| Residual VCM(ppm)(ISO 6401) | <1 | <1 | <1 | <1 | <1 |

| Grade | Applications |

|---|---|

| H-58 | Injection Moulding (Fitting), Blowing Moulding (Bottle). |

| H-61 | Injection Moulding (Pipe Fitting), Hollow-vacuum Forming (Bottle Blowing), Rigid Film, Shrinkable Film. |

| H-66 | Soft and Semi-rigid Product For General Purpose (PVC Film, Sheet, Beach Chair, Venetian Blind), Rigid Pipe, Hose, Wire and Cable Insulation |

| H-73 | High Impact Flexible Products (PVC Leather, Film, Furniture, Shoes), High Impact Sheet, High Voltage Wire and Cable Insulation. |

| H-80 | High Impact Flexible Products (PVC Leather, Film, Furniture, Shoes), High Impact Sheet, High Voltage Wire and Cable Insulation. |

| Product Application Area | Product range |

|---|---|

| Earthing, Lightning protection, General engineering, Electrical application, Busbar | Width : 20 mm to 250 mm Thickness : 3 mm to 30 mm Length : Mtrs to 8 Mtrs Length : Full Round/Slightly Round Edge/Square/Hard/Half-Hard?Annealed |

| ISS | ASTM | BS EN | Chemical Composition |

|---|---|---|---|

| B 187/C 10200 | 13601/CW008A | Cu 99.95% Min Oxygen 0.0010 | |

| B 187/C 10200 | 13601/CW008A | Cu 99.95% Min Oxygen 0.0010 | |

| ETP 191 Pt V | B 187/C 11000 | 13601/CW004A | Cu 99.9% Min |

| Standards | ASTM B 49- 10 ( Table 1: UNS number 10200) |

| Diameter | 8 mm to 16 mm |

| Size | 8 mm, 12.5 mm & 16mm |

| Packaging in | Wooden Pallet 1500 * 1500 mm and HDPE cover |

| Coils | 950 mm |

| Internal Diameter | 1500 mm |

| Outer Diameter Coil Weight | Upto 5 mt as per customer requirement (standard coil weight 1, 2.2, 3 & 4 mt) |

| UNS Number 11200 Copper Type | Unit | ASTM B49-09 | TDT Typical |

|---|---|---|---|

| Copper, min | % min | 99.90 | > 99.996 |

| Tellurium | ppm | 2 | < 1.0 |

| Selenium | ppm | 2 | <1.0 |

| Bismuth, max | ppm | 1 | 1 |

| Antimony max | ppm | 4 | 0.9 |

| Arsenic max | ppm | 5 | 1.16 |

| Tin, max | ppm | 5 | 0.42 |

| Lead max | ppm | 5 | 0.7 |

| Nickel max | ppm | 10 | 0.76 |

| Sulfur, max | ppm | 15 | 7-8 |

| Silver, max | ppm | 25 | 9.2 |

| Oxygen | ppm | <10 | <10 |

| % Elongation | % min | 30% min | >38 |

| Tensile strength | Min Mpa / N/mm2 | >170 | >170 |

| Surface Oxide | Angstrom max | 750 | <300 |

| Conductivity | % IACS | 100%Min | >102 |

| Diameter | Tolerance | +/-0.38 mm | < +/-0.20 |

| Product | Specification |

|---|---|

| B-211 | Aluminum and Aluminum Alloy Bar, Rod and Wire |

| B-233 | Aluminum Rod, 1350-H12, 1350-H14, 1350-H16 Drawing Stock. |

| B-398 | Aluminum Alloy 6201 Drawing Stock. |

| B-531 | Aluminum Alloy 5005 Drawing Stock. |

| B-800 | Standard Specification for 8000 Series. |

| Product | Specification |

|---|---|

| EC-1350 | Rod with conductivity in a range of 61 % to 63% IACS, and from 60 N/mm2 Up to 150 N/mm2. |

| 5005 | Rod with a minimum conductivity of 53.8% IACS, and from 95 N/mm2 up to 200 N/mm2. |

| 6101 | Rod with a conductivity of 50.5% up to 53% IACS, and from 160 N/mm2 Up to 220 N/mm2. Our continuous casting line also features continuous heat-treated 6101 rod. |

| 6201 | Rod with a conductivity of 50.5% up to 52.0% IACS, and from 170 N/mm2 Up to 230 N/mm2. |

| 8017 | Rod with a minimum conductivity of 58.5% up to 60.8% IACS, and from 115 N/mm2 to 140 N/mm2. |